Polymer Membranes: Types, Properties, and Key Applications in Separation Processes

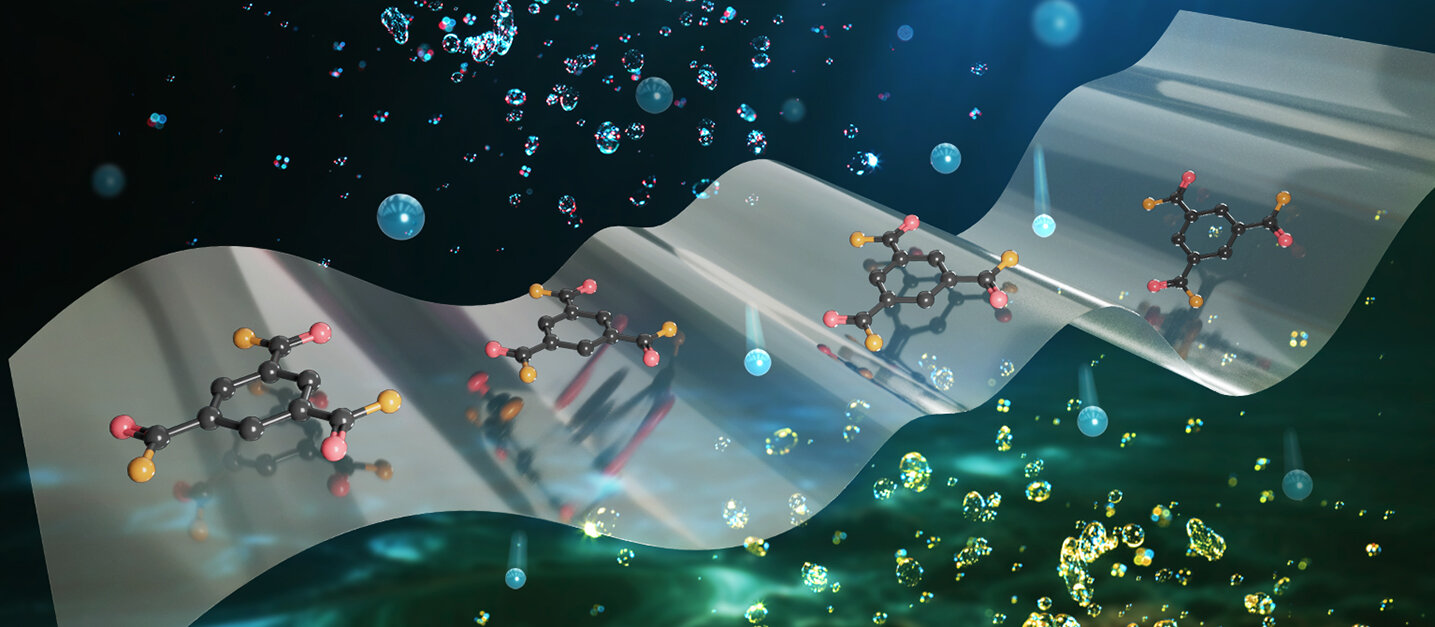

Polymer membrane is a thin, semi-permeable barrier made from synthetic or natural polymers that selectively allows the passage of certain molecules, ions, gases, or liquids while restricting others. These membranes are engineered for separation, filtration, purification, or controlled release applications across industries such as water treatment, energy, pharmaceuticals, food processing, and biomedical devices.

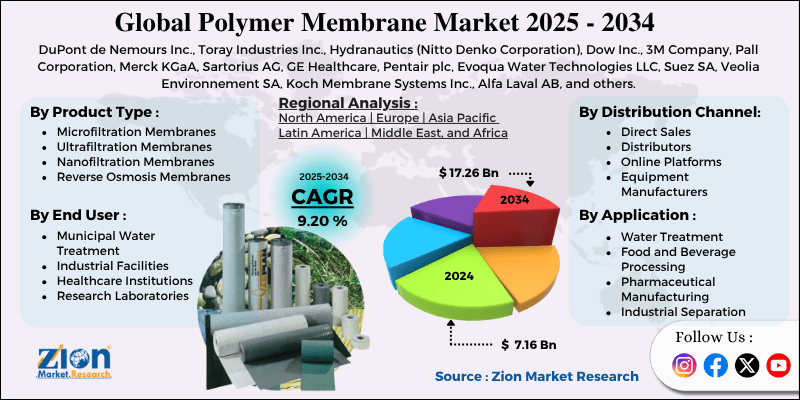

The concept of selective permeability dates to the 19th century with natural membranes (e.g., animal bladders), but synthetic polymer membranes emerged in the mid-20th century. The first commercial reverse osmosis (RO) membrane by Loeb and Sourirajan (1960s, asymmetric cellulose acetate) revolutionized desalination. Subsequent developments in polysulfone, polyamide, and advanced materials expanded capabilities. As of 2025, the global polymer membrane market is valued at approximately USD 30-40 billion, growing at 8-10% CAGR driven by water scarcity, energy transition (fuel cells, batteries), pharmaceutical purification, and sustainable separation processes. Key players include DuPont (FilmTec), Toray, Hydranautics, Suez (GE), Lanxess, and Asahi Kasei, with innovations focusing on fouling resistance, selectivity, and eco-friendly polymers.

Polymer Membranes bridge chemistry and engineering, enabling efficient, scalable separations that conserve energy and resources compared to distillation or evaporation.

Types of Polymer Membranes

Polymer membranes are classified by structure, material, and application:

- By Structure

- Symmetric (Isotropic): Uniform throughout; used in microfiltration.

- Asymmetric: Dense skin layer on porous support; higher flux (RO, UF).

- Composite/Thin-Film Composite (TFC): Ultra-thin selective layer (polyamide) on porous support; dominant in RO/NF.

- By Separation Mechanism

- Microfiltration (MF): 0.1-10 μm pores; particle removal.

- Ultrafiltration (UF): 0.001-0.1 μm; macromolecules, viruses.

- Nanofiltration (NF): 0.0001-0.001 μm; divalent ions, organics.

- Reverse Osmosis (RO): Dense; water from salts.

- Gas Separation: Selective gas permeation (CO₂/N₂, O₂/N₂).

- Pervaporation: Vapor separation (ethanol/water dehydration).

- Dialysis/Electrodialysis: Ion exchange.

- By Material

- Cellulosic: Cellulose acetate; early RO (declining).

- Polyamide: TFC skin; high salt rejection.

- Polysulfone/Polyethersulfone: Robust support layers.

- Polyvinylidene Fluoride (PVDF): Chemical resistance, MF/UF.

- Polytetrafluoroethylene (PTFE): Hydrophobic, gas/venting.

- Polypropylene (PP): Low-cost MF.

- Specialty: Perfluorinated (Aquivion for fuel cells), mixed-matrix (nanoparticles).

- By Configuration

- Flat sheet.

- Hollow fiber.

- Spiral-wound (dominant RO).

- Tubular.

Manufacturing Processes

- Phase Inversion Dominant for asymmetric membranes.

- Polymer solution cast; immersed in non-solvent bath → precipitation.

- Interfacial Polymerization TFC: Amine in water + acid chloride in organic → thin polyamide skin.

- Track-Etching Irradiation + etching for uniform pores.

- Stretching Semi-crystalline polymers for microporous.

- Electrospinning Nanofiber mats.

Sustainability: Solvent recovery, water-based systems.

Properties and Performance

Key metrics:

- Flux: Permeate volume/area/time.

- Selectivity/Rejection: % retained solute.

- Fouling Resistance: Bio/organic/inorganic.

- Chemical/Thermal Stability: pH 2-12, up to 80-100°C.

- Mechanical Strength: Burst pressure.

Enhancements: Zwitterionic coatings, nanoparticles, graphene oxide.

Applications

- Water Treatment (50%+ market)

- Desalination (RO).

- Wastewater reuse (UF/MF).

- Drinking water (virus/bacteria removal).

- Energy

- Proton exchange (PEM fuel cells).

- Battery separators (Li-ion).

- Gas separation (CO₂ capture).

- Food and Beverage

- Dairy concentration, juice clarification.

- Pharmaceuticals/Biotech

- Sterile filtration, virus removal, dialysis.

- Medical

- Hemodialysis membranes.

- Wound dressings.

- Industrial

- Solvent recovery, air filtration.

Advantages

- Energy-efficient vs. thermal separation.

- Compact/modular.

- Scalable.

- Selective.

Challenges

- Fouling (reduces flux).

- Trade-off permeability/selectivity (Robeson upper bound for gases).

- Cost (high-performance materials).

- End-of-life (recycling limited).

Market Trends

- Anti-fouling (zwitterionic, biomimetic).

- Thin-film nanocomposite (TFN).

- Bio-based polymers.

- Forward osmosis, membrane distillation hybrids.

- Asia-Pacific dominance (water stress).

Environmental Impact

- Positive: Energy savings in desalination.

- Concerns: Plastic waste, solvent use.

- Solutions: Biodegradable, recycled membranes.

Conclusion

Polymer membranes are transformative separation technologies enabling clean water, efficient energy, and pure products across industries. From asymmetric RO pioneers to advanced nanocomposite and fuel cell membranes, continuous innovation addresses fouling, selectivity, and sustainability. As global challenges—water scarcity, decarbonization, resource recovery—intensify, polymer membranes remain essential for efficient, selective processes in a circular economy. Ongoing materials science and manufacturing advances ensure their expanding role in solving pressing environmental and industrial needs.

More articles by ZMR Researche:

https://www.zionmarketresearch.com/de/report/clot-management-devices-market

https://www.zionmarketresearch.com/de/report/acellular-therapy-market

https://www.zionmarketresearch.com/de/report/assembly-automation-systems-market

https://www.zionmarketresearch.com/de/report/sous-vide-machine-market

https://www.zionmarketresearch.com/de/report/aromatic-compounds-market