Aluminum Composite Material: Lightweight Solutions for Modern Architecture

Aluminum Composite Material (ACM), also known as Aluminum Composite Panel (ACP), is a lightweight, rigid sandwich panel consisting of two thin aluminum sheets bonded to a non-aluminum core. This construction delivers exceptional strength-to-weight ratio, flatness, durability, and aesthetic versatility, making ACM a preferred cladding material in modern architecture, signage, transportation, and interior design.

Invented in Germany in the late 1960s by BASF (Alusuisse) under the brand Alucobond, ACM revolutionized facade systems by combining metal appearance with easy fabrication. Commercial production expanded globally in the 1980s-1990s, with brands like Reynobond (Arconic), Alpolic (Mitsubishi), and Larson emerging. As of 2025, the global ACM market is valued at approximately USD 8-10 billion, growing steadily due to urbanization, sustainable building trends, and demand for fire-rated variants post-safety concerns (e.g., Grenfell Tower 2017). Leading producers are in China, Europe, and North America, with applications spanning high-rise cladding, corporate signage, transportation vehicles, and modular construction.

Structure and Composition

ACM is a three-layer composite:

- Top Aluminum Skin 0.2-0.5 mm thick coil-coated aluminum (alloy 3000/5000 series); pre-painted with PVDF, polyester, or nano-ceramic coatings for weather/UV resistance.

- Core

- Polyethylene (PE): Standard, cost-effective, lightweight.

- Fire-Retardant (FR): Mineral-filled (magnesium hydroxide, aluminum hydroxide) for improved fire performance.

- Honeycomb or foam: For specialized stiffness/insulation.

- Bottom Aluminum Skin Similar to top; often primed or service-coated.

Total thickness: 3-6 mm standard; custom up to 10 mm. Widths: 1-2 meters; lengths unlimited via coil.

Bonding: Thermoplastic adhesive films under heat/pressure.

Properties and Performance

ACM excels in:

- Strength-to-Weight: High rigidity (bending stiffness) at low weight (~4-8 kg/m²).

- Flatness: Minimal bowing; ideal for large panels.

- Weather Resistance: PVDF coatings last 20-40 years; corrosion-resistant.

- Thermal/Acoustic Insulation: Core reduces heat transfer/sound.

- Fabrication: Easily cut, routed, bent, rolled for curved facades.

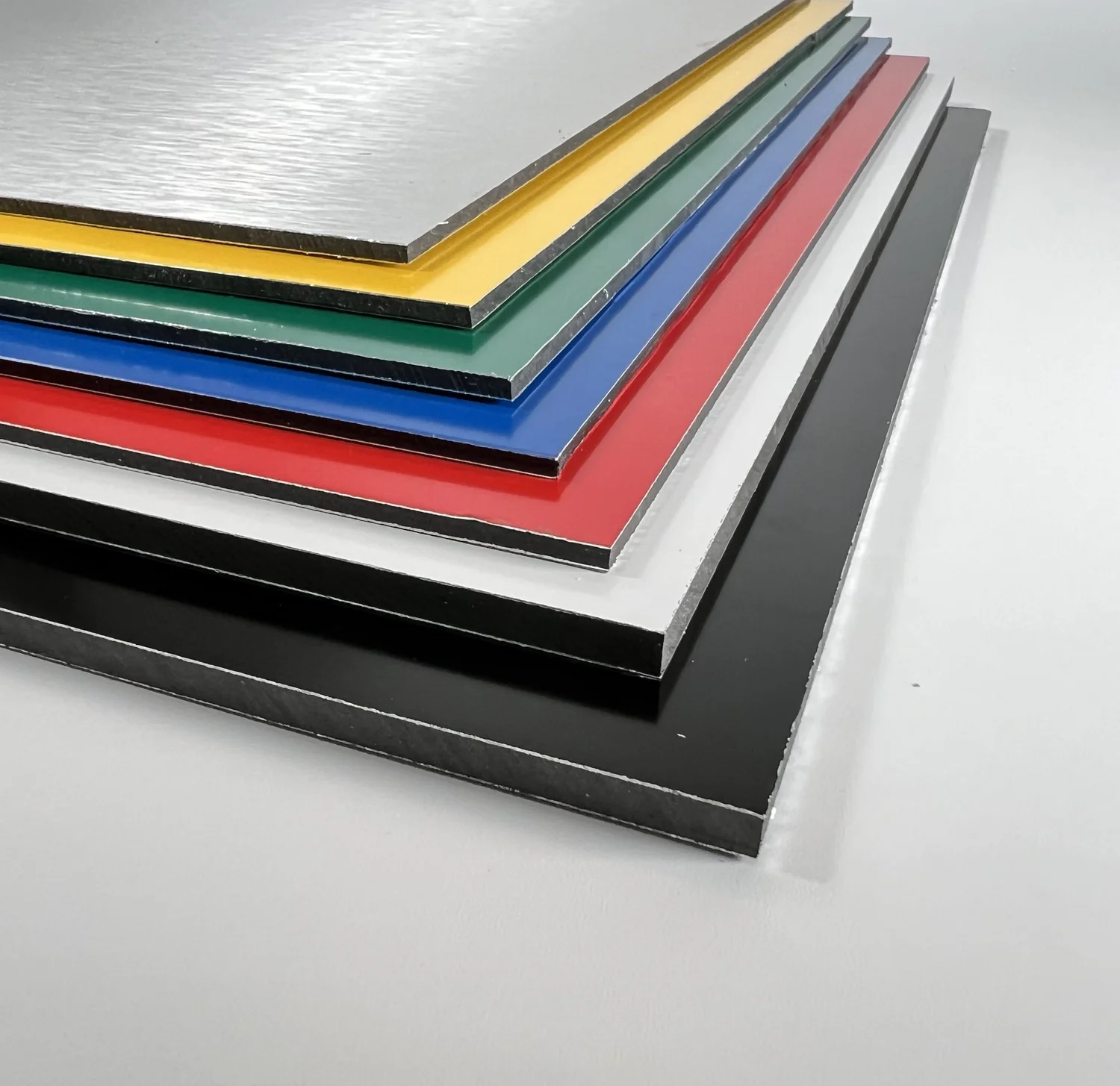

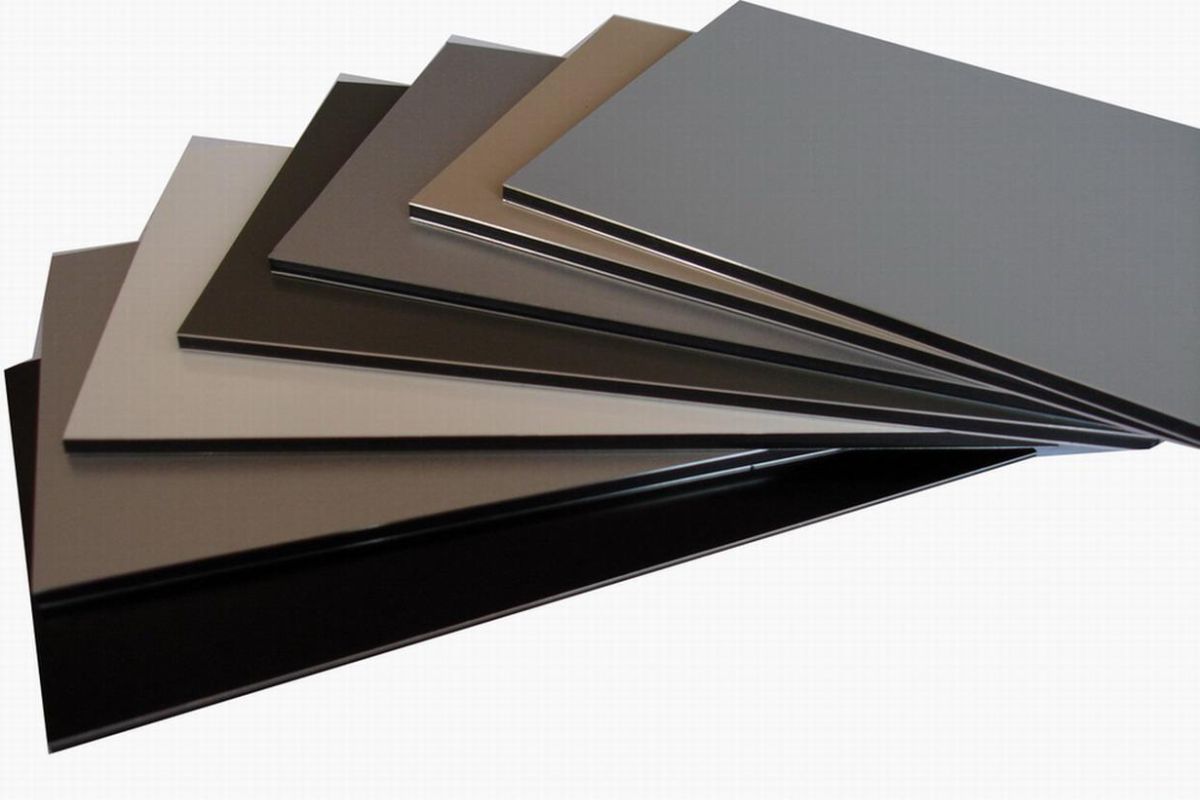

- Aesthetics: Unlimited colors, metallic finishes, digital printing, mimic stone/wood.

Fire performance varies:

- PE core: Highly combustible.

- FR/mineral core: Limited combustibility (Class A2/B1 ratings).

Post-2017 regulations mandate FR cores for high-rise (>18m in many jurisdictions).

Manufacturing Process

- Coil Coating: Aluminum coils painted, dried, laminated.

- Core Extrusion: PE or FR compound extruded into sheets.

- Continuous Lamination: Aluminum skins + core bonded under heat/pressure in double-belt press.

- Cooling and Cutting: Panels trimmed to size.

- Quality Control: Peel strength, flatness, coating adhesion tests.

Recyclable: Aluminum recoverable; core separation improving.

Applications

- Architectural Cladding Facades, curtain walls, soffits; iconic buildings (Burj Al Arab, Guggenheim Bilbao).

- Signage and Branding Corporate identity panels, billboards.

- Transportation Train/truck panels, aircraft interiors.

- Interior Design Partitions, ceilings, furniture.

- Renovation Over-cladding existing structures.

Advantages

- Lightweight: Reduces structural load.

- Cost-effective vs. solid metal.

- Design flexibility (curves, perforations).

- Fast installation (cassette/rainscreen systems).

- Low maintenance.

Limitations and Safety Considerations

- Fire Risk: PE-core ACM contributed to rapid fire spread in Grenfell; banned in many high-rise applications.

- Thermal Expansion: Requires ventilated rainscreen gaps.

- Acoustic: Limited sound insulation without additions.

- Durability: Coating degradation in harsh environments.

Modern FR cores and testing (NFPA 285, EN 13501) address safety.

Market Trends

- FR/mineral core dominance.

- Sustainable: Recycled aluminum, low-VOC coatings.

- Digital printing for custom graphics.

- BIM integration for design.

- Asia-Pacific growth (urbanization).

Environmental Impact

- Positive: Lightweight reduces building energy/transport emissions.

- Challenges: Mining bauxite energy-intensive; core recycling limited.

Lifecycle improvements: Cradle-to-cradle initiatives emerging.

Conclusion

Aluminum Composite Material revolutionized modern architecture with its blend of aesthetics, performance, and practicality. From iconic skyscrapers to everyday signage, ACM enables bold, durable designs at reasonable cost. Post-fire safety advancements with FR cores ensure responsible use, while sustainability focus aligns with green building standards. As fabrication techniques and materials evolve, ACM remains a versatile, enduring choice in contemporary construction and design.

More articles by ZMR Researche:

https://www.zionmarketresearch.com/de/report/gi-stool-testing-market

https://www.zionmarketresearch.com/de/report/quadricycle-and-tricycle-market

https://www.zionmarketresearch.com/de/report/ascites-market

https://www.zionmarketresearch.com/de/report/tendon-repair-market

https://www.zionmarketresearch.com/de/report/colon-cancer-diagnostic-market