Metal Powders for Additive Manufacturing: Key Materials and Properties Explained

Metal powders for additive manufacturing (AM), commonly known as 3D printing, are finely divided metallic particles engineered to precise specifications for layer-by-layer fabrication of complex metal parts. These powders serve as the raw material in powder bed fusion (PBF) processes like selective laser melting (SLM), direct energy deposition (DED), and binder jetting, enabling production of components with intricate geometries, reduced weight, and customized properties impossible or costly with traditional subtractive methods.

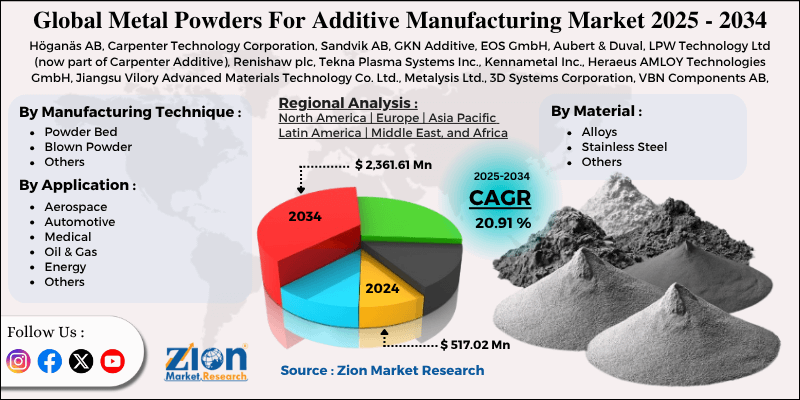

The use of metal powders in AM dates to the 1990s with early EOS and Concept Laser systems, but explosive growth occurred in the 2010s with aerospace (GE LEAP fuel nozzle) and medical (custom implants) adoption. As of 2025, the global metal powder for AM market is valued at approximately USD 1.5-2 billion, growing at 20-30% CAGR driven by aerospace, automotive electrification, medical devices, and defense applications. Annual powder consumption exceeds 5,000-10,000 tons, with demand for high-performance alloys outpacing supply chain capacity. Leading producers include Carpenter Additive, Sandvik, Höganäs, GKN Additive (now part of Melrose), AP&C (Arcam/GE Additive), EOS, and Tekna.

Metal Powders enable on-demand, low-waste manufacturing, but their quality—particle size, morphology, chemistry, and flowability—directly determines part density, mechanical properties, and repeatability.

Powder Characteristics and Specifications

Critical attributes for AM metal powders:

- Particle Size Distribution (PSD)

- Typical: 15-45 μm (laser PBF), 45-150 μm (DED/binder jetting).

- Narrow distribution (D10-D90) ensures packing density and flow.

- Morphology

- Spherical: Ideal (gas atomization); high flowability, dense packing (>99% density).

- Irregular/satellite-prone: Plasma or water atomized; poorer flow.

- Flowability

- Hall flow rate <25 s/50g; avalanche angle for spreadability.

- Apparent/Tap Density

-

50-60% theoretical for packing.

-

- Chemistry and Purity

- Oxygen <500-1,000 ppm (reactives like Ti); low inclusions.

- Microstructure

- Rapid solidification → fine grains, minimal segregation.

Standards: ASTM F3049 (guide), ISO/ASTM 52907 (characteristics).

Production Methods

- Gas Atomization (70-80% market)

- Molten metal stream disrupted by inert gas (Ar/N₂) jets.

- Spherical, clean powders; high yield.

- Variants: Vacuum inert gas (VIGA), electrode induction (EIGA) for reactives.

- Plasma Atomization

- Wire feedstock; ultra-spherical, low oxygen (Ti, superalloys).

- Water Atomization

- Irregular particles; cost-effective (steels).

- Emerging

- Plasma spheroidization (recycle irregular powder).

- Electrode atomization.

Recycling: Sieving/reuse common (up to 95% with quality control).

Common Materials

- Titanium Alloys (Ti6Al4V dominant) Aerospace, medical; high strength/weight, biocompatibility.

- Nickel Superalloys (Inconel 718, 625) Turbines, high-temperature.

- Stainless Steels (316L, 17-4PH) General industrial, corrosion-resistant.

- Aluminum Alloys (AlSi10Mg) Lightweight automotive/aerospace.

- Cobalt-Chrome Medical implants, dental.

- Tool Steels (H13, maraging) Molds, tooling.

- Copper Alloys Heat exchangers (emerging).

- Refractories (tungsten, molybdenum—research).

Precious: Gold, silver for jewelry/electronics.

Applications

- Aerospace Complex, lightweight parts (GE fuel nozzles).

- Medical Custom implants, porous structures.

- Automotive EV components, prototypes.

- Energy Turbine blades, heat exchangers.

- Defense Rapid prototyping, lightweight armor.

- Tooling Conformal cooling inserts.

Advantages of Powder-Based AM

- Design freedom (lattice, topology optimization).

- Material efficiency (near-net-shape).

- Customization.

- Supply chain resilience (on-demand).

Challenges

- Cost: Powder USD 50-500/kg (Ti ~USD 300-500).

- Quality Control: Batch variability, oxygen pickup.

- Post-Processing: HIP, heat treatment.

- Scalability: Powder supply bottlenecks.

- Safety: Reactive powders (Ti fire risk).

Market Trends

- High-entropy alloys.

- Recycled/reused powder.

- Larger particle for DED.

- Bio-compatible (Ti with low oxygen).

- Asia-Pacific supply growth.

Environmental and Sustainability Aspects

- Reduced waste vs. machining.

- Challenges: Energy-intensive atomization, rare metals.

- Recycling rates >90%.

Conclusion

Metal powders for additive manufacturing enable revolutionary design and performance in high-value industries, with spherical, controlled powders delivering near-full density parts. Continuous advances in atomization, materials (refractories, copper), and recycling address cost and supply constraints. As AM matures from prototyping to serial production—particularly in aerospace, medical, and energy—metal powders remain the critical feedstock driving innovation and sustainability in advanced manufacturing. Quality assurance and standardization will further accelerate adoption.

More articles by ZMR Researche:

https://www.zionmarketresearch.com/de/report/track-dumper-market

https://www.zionmarketresearch.com/de/report/vr-fitness-game-market

https://www.zionmarketresearch.com/de/report/vegetable-hpmc-capsule-market

https://www.zionmarketresearch.com/de/report/cell-line-development-market

https://www.zionmarketresearch.com/de/report/digital-gaussmeters-market