Polyurea Greases: High-Performance Lubricants for Extreme Conditions

Polyurea Greases are a specialized class of lubricating greases that use polyurea compounds as thickeners, distinguishing them from traditional soap-based (lithium, calcium, aluminum) or non-soap (clay, silica) greases. The thickener is formed by the reaction of isocyanates with amines, creating a urea linkage network that traps base oil and additives. Polyurea greases are renowned for their excellent thermal stability, mechanical shear resistance, water resistance, and long service life, making them ideal for demanding applications.

Developed in the 1950s and commercialized in the 1970s, polyurea greases gained prominence in the 1980s-1990s as high-performance alternatives to lithium greases, especially in electric motors and automotive wheel bearings. By 2025, they hold a significant share of the premium grease market (estimated 10-15% globally), valued within the broader USD 6-7 billion industrial lubricants sector. Growth is driven by electrification (EV motors), wind energy, and food-grade requirements, with major producers including ExxonMobil (Mobil Polyrex EM), Shell, Klüber Lubrication, and Chevron.

Chemical Composition and Thickener Structure

The polyurea thickener is typically diurea, tetraurea, or complex variants:

- Diurea: Formed from one diisocyanate and two monoamines.

- Tetraurea: One diisocyanate with two diamines, offering superior high-temperature performance.

- Complex Polyurea: Mixtures or reactions with fatty acids for enhanced properties.

Common base oils include mineral, synthetic hydrocarbons (PAO), or esters. Additives encompass antioxidants, extreme pressure (EP) agents, corrosion inhibitors, and solid lubricants (molybdenum disulfide, graphite). NLGI grades range from 000 (semi-fluid) to 3, with most electric motor greases at NLGI 2.

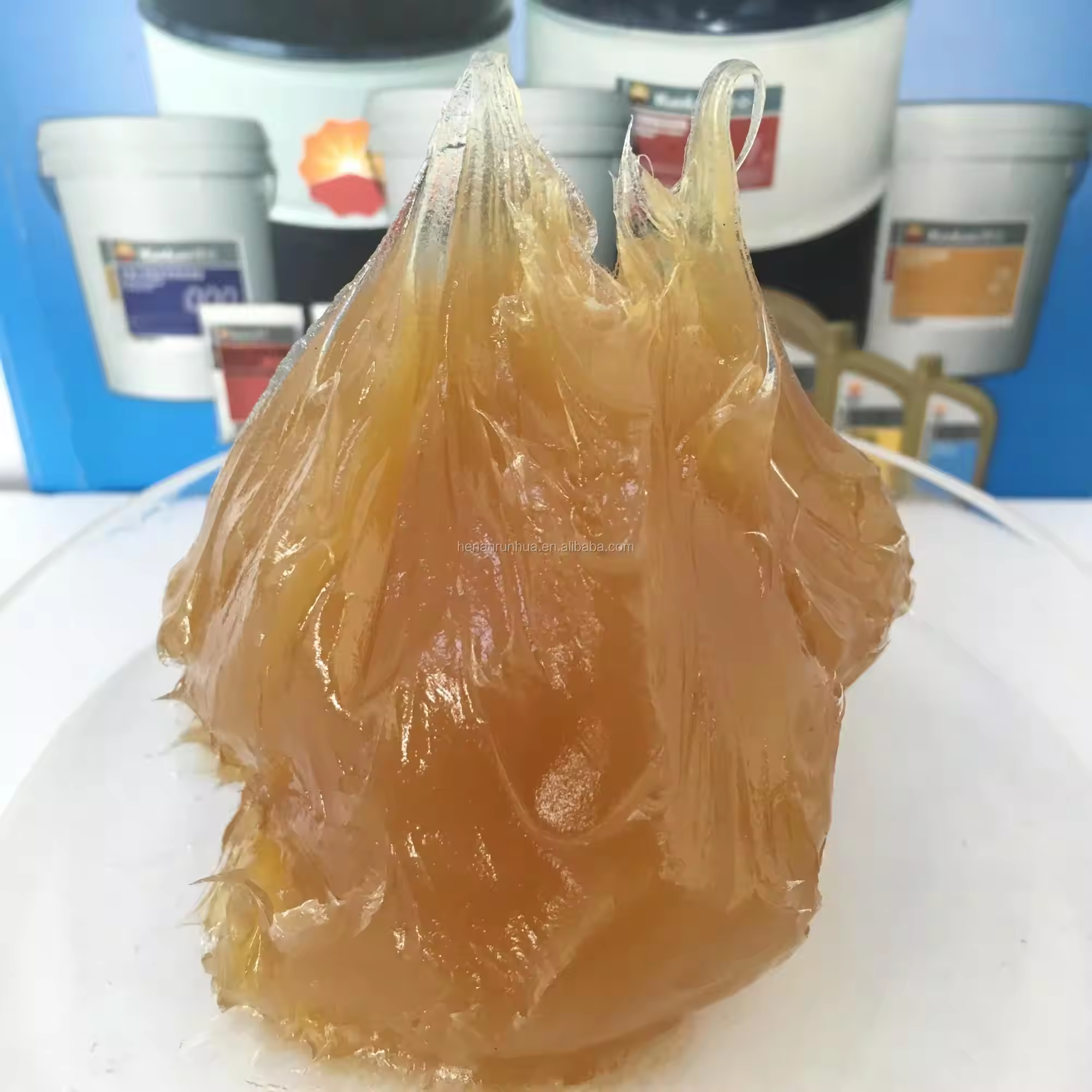

The thickener forms a fibrous, sponge-like matrix (10-20% by weight) that provides reversible shear thinning and excellent pumpability.

Key Properties and Advantages

Polyurea greases excel in:

- Thermal Stability: Dropping points >240-300°C (vs. 180-200°C for lithium); suitable for continuous operation up to 150-180°C.

- Oxidation Resistance: Minimal hardening or oil bleed at high temperatures.

- Mechanical Stability: Excellent shear resistance; minimal softening under prolonged working.

- Water Resistance: Superior washout resistance; ideal for wet environments.

- Long Life: Extended relubrication intervals (2-5x longer than lithium in many applications).

- Compatibility: Generally compatible with lithium/lithium-complex greases (unlike some calcium sulfonates).

Limitations include potential incompatibility with certain clays or sodium soaps, and higher cost (20-50% premium).

Production Methods

Manufacturing involves controlled reaction chemistry:

- Isocyanate and Amine Reaction: In base oil at 60-100°C, forming urea thickener in situ.

- Heating/Cooling Cycle: To 150-200°C for structure development, then cooling.

- Additive Incorporation: Post-thickening blending.

- Homogenization/Milling: For uniform texture.

Safety is critical due to isocyanate toxicity; modern plants use closed systems. Food-grade versions (NSF H1) avoid aromatic amines.

Applications

Polyurea greases dominate in:

- Electric Motors: Blue-dyed variants (e.g., Mobil Polyrex EM) for low noise, long life in sealed bearings.

- Automotive: Wheel bearings, CV joints (high-speed stability).

- Industrial: Steel mills, paper machines, robotics (high temperature/shear).

- Wind Turbines: Main bearings, generators (extended intervals).

- Food Processing: H1-registered for incidental contact.

- Mining/Construction: Heavy equipment in harsh conditions.

They are less common in general chassis lubrication (lithium preferred for cost).

Performance Standards and Testing

Key specifications:

- NLGI GC-LB: Automotive chassis/wheel bearing (polyurea often exceeds).

- ASTM D4950: Performance classification.

- DIN 51825: European standards (KP grades for EP).

Testing includes dropping point (ASTM D2265), roll stability (D1831), water washout (D1264), oxidation stability (D942), and four-ball wear (D2266).

Market Trends and Innovations

In 2025:

- Electrification: Demand surges for EV motor bearings.

- Sustainability: Bio-based polyurea thickeners emerging.

- Food-Grade Growth: Clean-label processing.

- High-Performance Variants: Graphene-enhanced or hybrid thickeners.

Asia-Pacific leads production; Europe/North America focus on premium applications.

Health, Safety, and Environmental Considerations

Polyurea greases are generally non-toxic once manufactured, but production involves hazardous isocyanates requiring strict controls. Used grease disposal follows standard lubricant protocols. Low volatility reduces emissions; some formulations are biodegradable.

Conclusion

Polyurea greases represent a high-performance niche in lubrication technology, offering unmatched durability in extreme conditions. Their adoption in critical applications like electric motors and renewable energy underscores their value in modern industry. As equipment demands increase, polyurea formulations will continue evolving for efficiency, longevity, and sustainability.

More articles by ZMR Researche:

https://www.zionmarketresearch.com/de/report/paper-cushion-machines-market

https://www.zionmarketresearch.com/de/report/paprika-market

https://www.zionmarketresearch.com/de/report/smart-pet-feeder-market

https://www.zionmarketresearch.com/de/report/over-the-counter-otc-hearing-aids-market

https://www.zionmarketresearch.com/de/report/point-of-sale-display-market