Silver Sintering Paste: The Future of High-Performance Die Attach in Power Electronics

Silver sintering paste is a high-performance conductive adhesive material composed primarily of micro- or nano-sized silver particles suspended in an organic vehicle (solvents, binders, dispersants). It is designed for die-attach and interconnection in power electronics, enabling robust, void-free metallic bonds through a low-temperature sintering process. Unlike traditional solders that melt and reflow, silver sintering forms solid-state diffusion bonds, creating a pure silver interconnect with exceptional thermal and electrical conductivity.

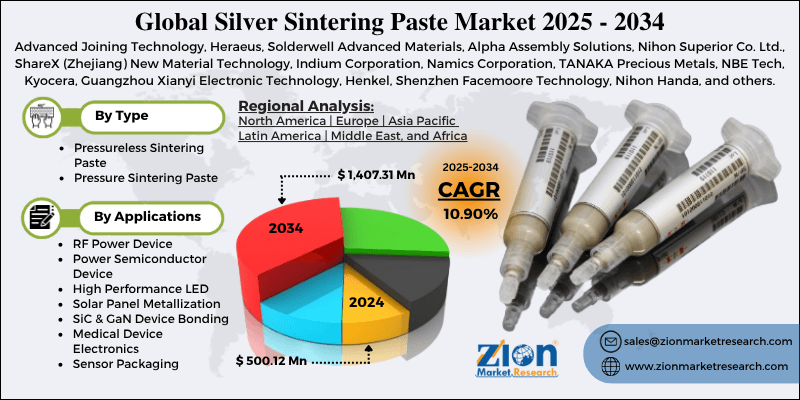

The technology emerged in the early 2000s as an alternative to high-lead solders for high-reliability applications, gaining traction with wide-bandgap semiconductors (SiC, GaN) requiring operation above 200°C. As of 2025, silver sintering paste is critical for electric vehicles (EVs), renewable energy inverters, 5G infrastructure, and aerospace electronics. The market is valued at USD 200-500 million (estimates vary by scope), growing rapidly due to power density demands and lead-free regulations. Leading manufacturers include Heraeus Electronics (mAgic series), Indium Corporation (InFORCE/InBAKE), Kyocera, Henkel, Alpha Assembly Solutions (MacDermid Alpha), and Tanaka Precious Metals.

Silver Sintering Paste addresses limitations of solder (low melting point, voids) and epoxy (poor conductivity), offering 5-10x longer lifetime in thermal cycling for high-power devices.

Composition and Formulation

Typical silver sintering paste contains:

- Silver Particles: 70-95 wt% micro/nano-flakes or spheres (0.1-10 μm) for dense packing.

- Organic Vehicle: Solvents (terpineol, alcohols), binders (resins), dispersants for rheology.

- Additives: Flux-like agents, reducing compounds for oxide removal.

Variants:

- Pressure Sintering: High silver loading; requires 10-30 MPa.

- Pressureless: Optimized organics for open-air/low-temp sintering.

- Hybrid/Semi-Sintering: Resin + silver for easier processing.

Particle shape (flakes vs. spheres) influences porosity and conductivity.

Sintering Process

Sintering transforms paste into a metallic bond:

- Dispensing/Printing: Stencil, jetting, or needle on substrate/die.

- Drying: 100-150°C to evaporate solvents.

- Sintering: 200-300°C (pressure or pressureless); particles diffuse/neck, organics burn off.

- Cooling: Forms dense silver network.

Pressure-assisted: Faster, denser. Pressureless: Compatible with standard reflow ovens.

Time: 30-120 minutes; nitrogen/forming gas atmosphere optional.

Result: Porosity <5-10%, bond strength >40 MPa.

Advantages

- Thermal Conductivity: 150-300 W/m·K (3-5x solder).

- Electrical Conductivity: Near bulk silver.

- Reliability: 5-15x longer thermal cycling life (no melting).

- High-Temperature Operation: >200-250°C continuous.

- Void-Free Joints: Better heat dissipation.

- Lead-Free: RoHS compliant.

Ideal for SiC/GaN power modules, EVs, aerospace.

Disadvantages

- Cost: High silver content (USD 20-50/g processed).

- Process Sensitivity: Precise temperature/profile; oxidation risk.

- Pressure Variants: Equipment investment.

- Bond Line Control: Thickness critical (20-50 μm).

- Limited Flexibility: Brittle pure silver joints.

Applications

- Power Electronics Die-attach in IGBT/SiC modules (EVs, inverters).

- Semiconductors LED packaging, RF devices.

- Automotive EV powertrain, sensors.

- Aerospace/Defense High-reliability modules.

- Renewables Solar inverters, wind power converters.

Emerging: Large-area sintering for modules.

Market and Manufacturers

Market size: USD 200-500 million (2025 estimates); growth from EV/SiC boom. Key players:

- Heraeus (mAgic series).

- Indium Corp (InFORCE pressure, InBAKE pressureless).

- Kyocera, Henkel, Alpha (MacDermid).

- Tanaka, Namics, Jufeng.

Asia dominant (production); Europe/North America innovation.

Conclusion

Silver sintering paste revolutionizes high-power electronics interconnection, delivering superior thermal/electrical performance and reliability for demanding applications like EVs and wide-bandgap devices. Pressure and pressureless variants offer flexibility, with ongoing reductions in cost and process complexity driving adoption. As power density increases and lead solders phase out, silver sintering remains essential for next-generation electronics, balancing premium performance with manufacturing practicality.

More articles by ZMR Researche:

https://www.zionmarketresearch.com/de/report/oil-accumulator-market

https://www.zionmarketresearch.com/de/report/plenoptic-camera-market

https://www.zionmarketresearch.com/de/report/marine-winches-market

https://www.zionmarketresearch.com/de/report/thick-film-ceramic-substrates-market

https://www.zionmarketresearch.com/de/report/high-purity-boehmite-market