Thioglycolate in Cosmetics, Pharmaceuticals, and Industry

Thioglycolic acid (TGA), also known as mercaptoacetic acid, is an organic compound with the formula HSCH₂CO₂H, featuring both a thiol (mercaptan) and a carboxylic acid functional group. This colorless liquid possesses a strongly unpleasant odor reminiscent of rotten eggs and is miscible with polar organic solvents, including water. Developed in the 1940s primarily as a chemical depilatory, TGA’s discovery traces back to the early 1930s when scientist David R. Goddard identified it as a reagent for reducing disulfide bonds in proteins like keratin in hair.

Its IUPAC name is sulfanylacetic acid, with synonyms including 2-sulfanylacetic acid, 2-mercaptoacetic acid, acetyl mercaptan, mercaptoacetate, mercaptoacetic acid, thioglycolic acid, and thiovanic acid. Key identifiers include CAS number 68-11-1, PubChem CID 1133, EC number 200-677-4, and UN number 1940 (classified under DOT Hazard Class 8 for corrosives). Global production focuses on its versatility in cosmetics, pharmaceuticals, and industrial applications, with increasing emphasis on sustainable manufacturing due to environmental regulations and consumer demand for greener chemicals. TGA is often used in salt forms, such as sodium or calcium thioglycolate, to enhance stability and efficacy in various products.

Chemical and Physical Properties

TGA has a molecular formula of C₂H₄O₂S and a molar mass of 92.11 g/mol. It is a clear, colorless liquid with a density of 1.32 g/cm³, a melting point of −16 °C (3 °F; 257 K), and a boiling point of 96 °C (205 °F; 369 K) at 5 mmHg. The vapor pressure is 10 mmHg at 17.8–18 °C, and it is fully miscible with water. Its magnetic susceptibility is −50.0·10⁻⁶ cm³/mol, and it exhibits a flash point greater than 110 °C (230 °F; 383 K), with explosive limits starting at 5.9%. Chemically, TGA is a stronger acid than acetic acid, with pKa values of 3.83 for the carboxylic acid group (HSCH₂CO₂H → HSCH₂CO₂⁻ + H⁺) and 9.3 for the thiol group (HSCH₂CO₂⁻ → ⁻SCH₂CO₂⁻ + H⁺). It acts as a reducing agent, particularly at higher pH, oxidizing to dithiodiglycolic acid: 2 HSCH₂CO₂H + “O” → [SCH₂CO₂H]₂ + H₂O. TGA forms complexes with metal ions like iron, molybdenum, silver, and tin, often as its dianion, and reacts with compounds such as diethyl acetylmalonate. It is incompatible with oxidizing agents, strong bases, chemically active metals, and air, potentially leading to hazardous reactions. The compound is combustible, producing poisonous sulfur oxides in fires.

Production Methods

TGA is primarily produced by reacting sodium or potassium chloroacetate with alkali metal hydrosulfide in an aqueous medium: ClCH₂CO₂Na + NaSH → HSCH₂CO₂Na + NaCl, followed by acidification to yield the free acid. An alternative method involves the Bunte salt intermediate: ClCH₂CO₂H + Na₂S₂O₃ → Na[O₃S₂CH₂CO₂H] + NaCl, then hydrolysis: Na[O₃S₂CH₂CO₂H] + H₂O → HSCH₂CO₂H + NaHSO₄. Other processes include heating hydrogen sulfide with carboxylic acid derivatives or using sodium thiosulfate with sodium monochloroacetate in water, followed by hydrolysis. A continuous synthesis under common pressure uses chloroacetic acid and sodium hydrosulfide in combined reactors, optimizing efficiency. Historical methods involve electrolysis of dithioglycolic acid or dropwise addition of chloroacetic acid to sodium hydrosulfide at normal temperature. For purification, the barium salt can be treated with hydrochloric acid and extracted with ether. Industrial trends emphasize reducing waste and emissions through greener raw materials to comply with tightening regulations.

Applications and Uses

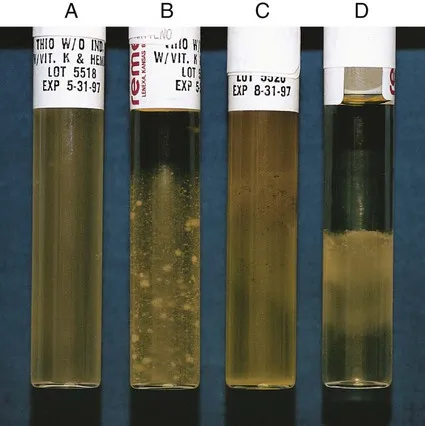

TGA’s primary use is in personal care products, accounting for over 50% of its application volume, particularly in hair removal creams where it breaks down keratin for effective depilation, offering faster application and smoother results. It serves as a precursor to ammonium thioglycolate in hair permanents, reducing disulfide bonds to allow reshaping. In pharmaceuticals, TGA acts as an intermediate in API synthesis, leveraging its reducing properties for high-yield, low-impurity production under GMP standards. Agrochemical applications include synthesizing herbicides and fungicides, promoting sustainable farming by minimizing harsher chemicals and improving crop yields. In polymer and resin manufacturing, it functions as a chain transfer agent or cross-linker, enhancing durability in coatings and adhesives. Research and chemical synthesis utilize TGA for developing new entities and testing pathways due to its predictable reactivity. Other uses encompass leather processing for depilation, bacteriological media like thioglycolate broth, nail softening for medical treatments, PVC stabilization via organotin derivatives, and iron oxide removal in cleaners. Calcium thioglycolate aids in environmental remediation by adsorbing heavy metals.

Health and Safety Considerations

TGA poses acute toxicity risks, with LD₅₀ (oral, rat) at 261 mg/kg, LC₅₀ (inhalation, rat) at 21 mg/m³ for 4 hours, and LD₅₀ (dermal, rabbit) at 848 mg/kg. Contact severely irritates and burns skin and eyes, potentially causing permanent damage, while inhalation irritates the respiratory tract, leading to coughing and shortness of breath. Repeated exposure may cause skin rashes or sensitization, though no data confirms chronic effects like carcinogenicity or reproductive toxicity. GHS labels include hazards H301+H311+H331 (toxic if swallowed, contacted, or inhaled) and H314 (severe burns). Precautionary measures emphasize ventilation, protective gear (e.g., butyl rubber gloves, goggles), and avoiding ingestion or ignition sources. First aid involves immediate flushing for eyes/skin and removal to fresh air for inhalation, with medical attention required. No specific medical tests exist, but monitoring is advised for suspected overexposure.

Environmental Impact

Thiochemicals like TGA exhibit relatively high aquatic toxicity, resulting in low predicted no-effect concentrations (PNECs). Ecotoxicity data gaps are filled via in silico methods, read-across, and limited testing (e.g., algae, daphnia), replacing over 60% of required vertebrate tests. Preliminary predicted environmental concentrations (PECs) for production sites indicate no risk to aquatic compartments, with PEC/PNEC ratios below concern levels. However, downstream uses must ensure PECs do not exceed PNECs. TGA may be harmful to aquatic life with long-lasting effects and should not be released into the environment. Classification under REACH and CLP considers its potential for environmental hazards, with integrated testing strategies (ITS) aiding assessments.

Regulations and Recommendations

Occupational exposure limits include NIOSH REL TWA 1 ppm (4 mg/m³) [skin], ACGIH TLV TWA 1 ppm (8-hour shift), and OSHA PEL none established, focusing on skin absorption risks. IDLH is not determined, but monitoring uses methods like thin-layer chromatography or gas chromatography. Storage requires cool, ventilated areas in tightly closed containers away from incompatibles, with spills contained using absorbents like vermiculite. REACH mandates integrated testing for aquatic toxicity, with exposure-based waiving for low-risk substances. Work health and safety laws vary by jurisdiction; consult regulators for compliance. Ongoing innovations aim to enhance sustainability amid tightening regulations.

More articles by ZMR Researche:

https://www.zionmarketresearch.com/de/report/confidential-computing-market

https://www.zionmarketresearch.com/de/report/floating-production-storage-and-offloading-fpso-market

https://www.zionmarketresearch.com/de/report/sodium-lactate-market

https://www.zionmarketresearch.com/de/report/silicon-on-insulator-market

https://www.zionmarketresearch.com/de/report/alkylate-market