The smallest transistor ever created by combining two atom-thin materials

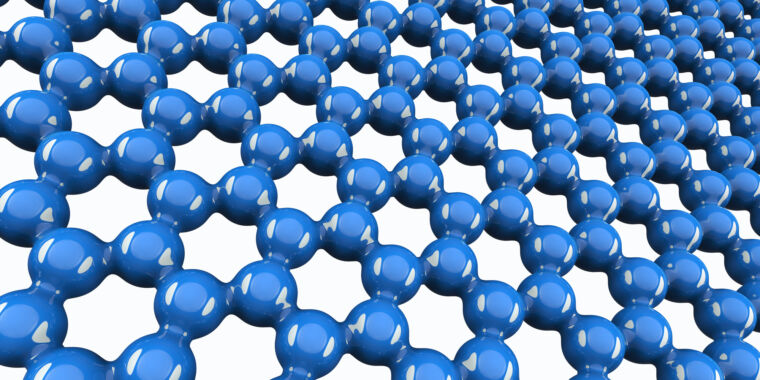

Transistors etched in silicon have always required cutting-edge manufacturing technologies to keep pace with their ever-shrinking features. Although atomically thin materials like graphene and carbon nanotubes have been discovered, the inherent features of these materials may be able to replace our production demands. A carbon nanotube that is 1 nanometer wide can be used instead of having to carve a 1 nanometer feature into silicon.

And there have been some remarkable accomplishments, such as the construction of a 1 nanometer carbon nanotube gate. For a working device, the atomically thin materials must be placed precisely, which is a tough task. There is also a lot of heavier hardware in the system that is based on transistor design techniques.

It has been stated that the shortest transistor gate length has ever been documented in a new research published this week. One carbon atom is all it takes to set a new world record in a graphene sheet. To make the transistor even more compact, the designers used a second, atomically thin material for a crucial component (in addition to a creative arrangement of components).

Going nuclear

The source and drain electrodes of a transistor are separated by a semiconductor from one another in a conventional transistor configuration. The gate, a third conductive electrode, determines whether the semiconductor is conducting or insulating. When it comes to transistor size, the gate length is one of the most critical measurements.

The most well-known semiconductor is silicon, although atomically thin semiconductors exist as well. Molybdenum disulfide is the most well-known of these compounds. Molybdenum disulfide, although being somewhat thicker than a single atom due to the arrangement of its chemical bonds, is nevertheless very compact. The researchers picked molybdenum disulfide as their semiconducting material because it has beneficial features, is well-characterized, and is straightforward to deal with. All that was required for the molybdenum disulfide contact electrodes were thin metal strips.

The gate was closed. A single carbon nanotube served as the gate in the preceding 1-nanometer device. It’s tough, but not impossible, to get smaller than that. Carbon atoms are bonded together to form a thin sheet called graphene. Even though the sheet will be far bigger than a nanotube in length and breadth, it will only have a thickness of one carbon atom. As a result, a very short gate length might be achieved by using the sheet edge of graphene as the gate.

However, all of these materials have already been employed in a variety of different test equipment. In the new work, the arrangement of the pieces is the key to its success. In order to use the graphene sheet’s edge as a gate, this configuration necessitates some of the other components as well. In addition, the design is rather straightforward to produce, as neither of the atomically thin materials requires particularly accurate alignment.

Ingenious use of angles and angles

Layers of silicon and silicon dioxide were the starting point for the device’s construction. The transistor does not include any silicon; it is entirely structural. The gate material was created by layering a graphene sheet on top of silicon and silicon dioxide. They then added an aluminium coating on top of it. While aluminium is a conductor, the surface oxidised to aluminium oxide after a few days of exposure to the air. The graphene sheet was placed atop silicon dioxide and aluminium oxide, both of which are insulators, respectively. Aside from the graphene’s edge, nothing else was connected to the transistors.

The researchers used a simple etching technique to reveal the graphene’s edge, which was done by etching along the aluminum’s edge into the silicon dioxide below. Using this method, a linear edge was exposed on the graphene sheet, which may be utilised as a gate. A thin coating of hafnium oxide covers the whole device at this stage, acting as an insulator to separate the gate from the rest of the circuitry.